The human body gets energy from two main sources: sugars and fat. There is always a balance between the two energy sources that shifts from one to the other depending on the availability of each. However, with a metabolic disorder such as diabetes – where the body is unable to use sugars for energy – the balance is unintentionally tipped, with serious consequences to a person’s health and wellbeing.

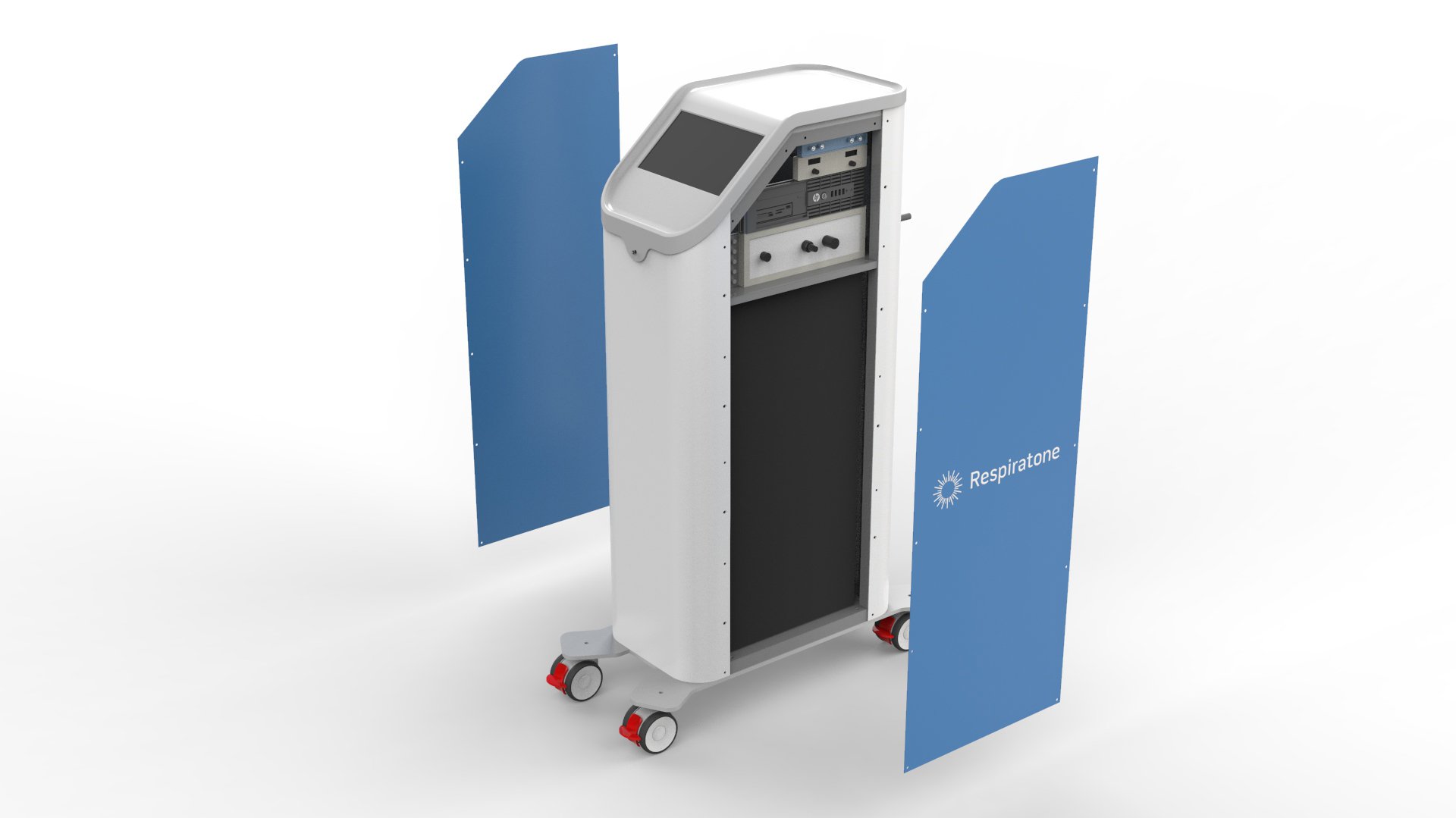

An academic team, led by Dr David Carty, Associate Professor of the Joint Quantum Centre at Durham University, created a device that can detect metabolic imbalances by measuring the levels of acetone expelled in our breath. When fat is metabolised by the body, ketones (including acetone) are produced. The acetone is then expelled from the body in urine, sweat, and also via the lungs as a gas. The aptly named ‘Respiratone’ is a fully integrated, mobile device, that can measure and analyse acetone levels in the breath extremely well, on the go.

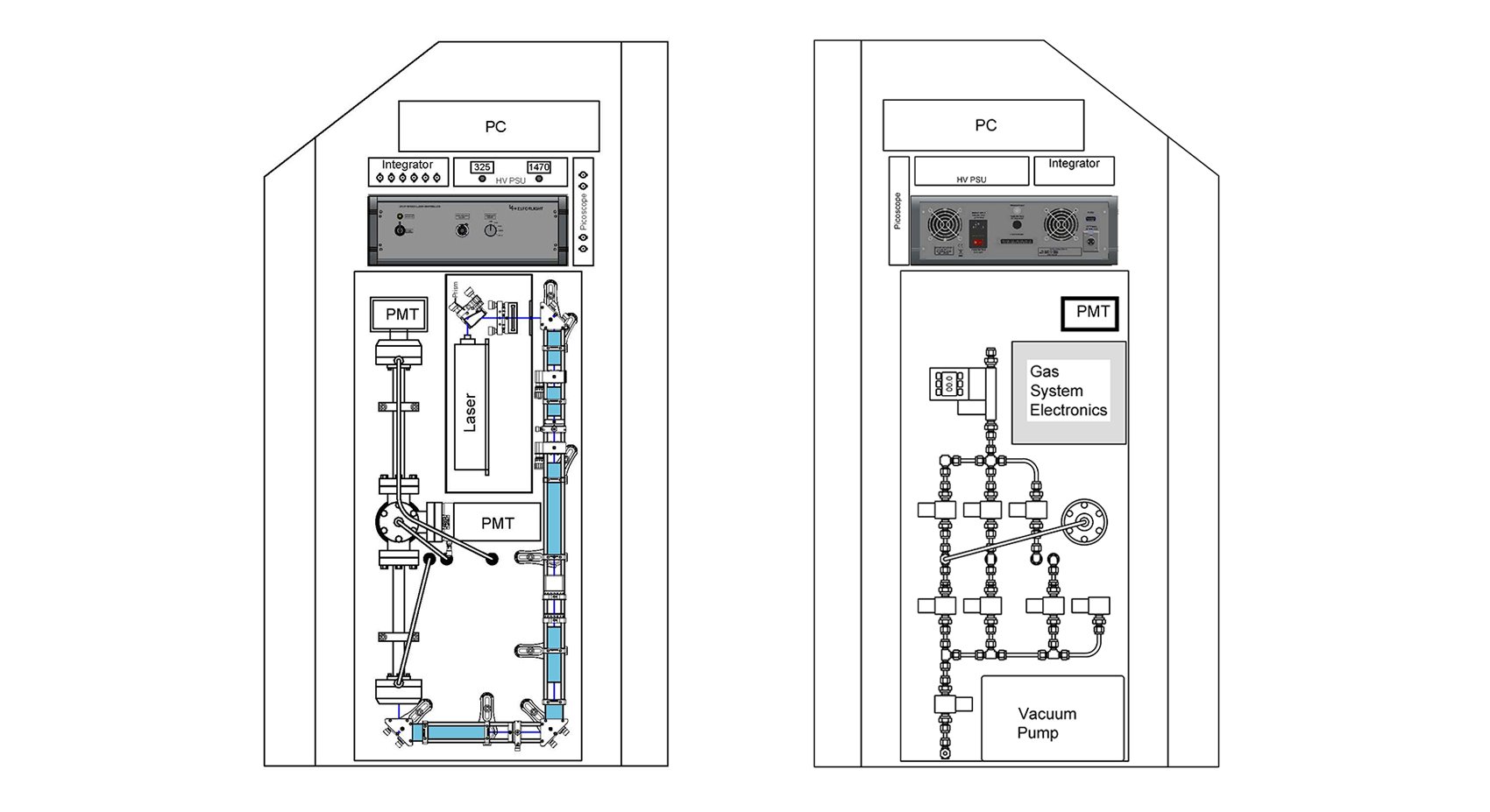

The University’s fully functioning working prototype

The team at Durham University had already developed a fully functioning working prototype that could measure acetone gas molecules using laser technology. However, being a first-of-a-kind, it was quite an industrial set-up. To get it to the next stage they needed to obtain clinical key opinion leaders and attract investment, so required our help in developing the Respiratone into a more viable medical product.

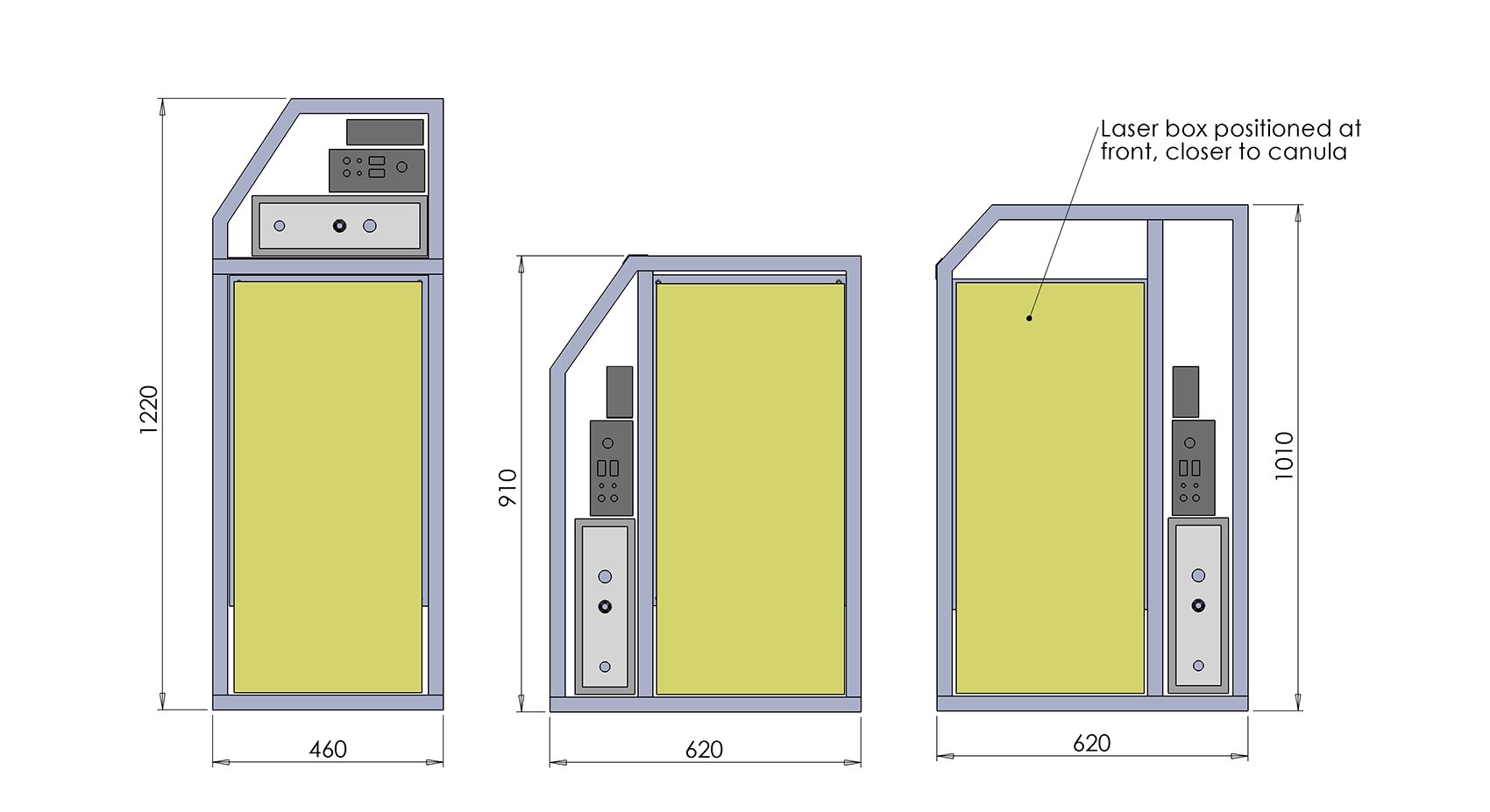

To achieve this, we reverse engineered the University’s prototype and rebuilt it from the ground up. Taking detailed measurements of each component, we developed a basic CAD model to play around with its size and shape. We then started sketching, considering – from a user’s perspective – the positioning of the monitor, handles, cannula storage, and removable maintenance panels.

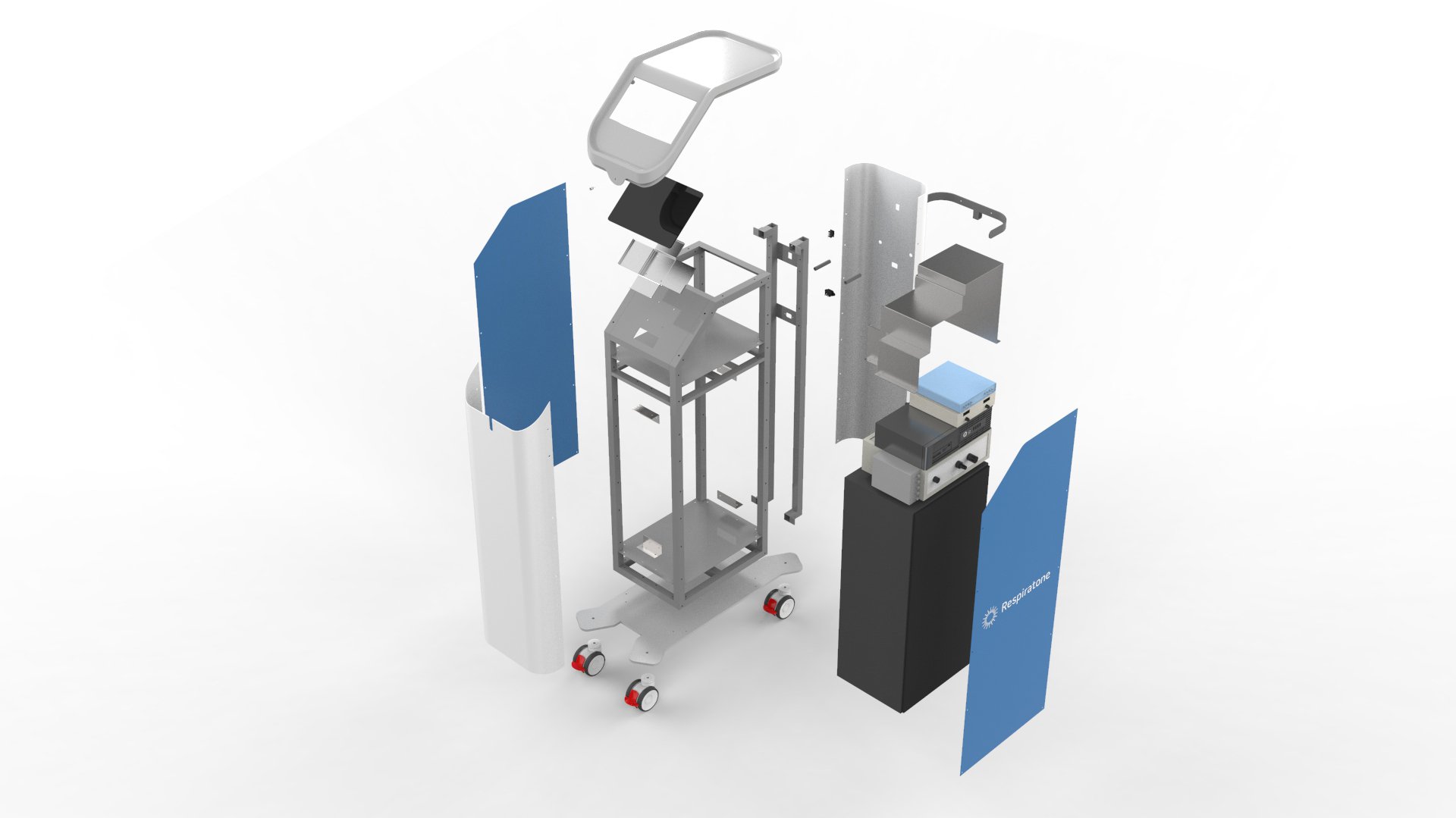

We went through several CAD iterations, developing the chassis and understanding the most effective way of mounting the internal components to both reduce space and improve accessibility – each time informing how the unit should be assembled and address medical device regulations.

Early CAD iterations

As a VR demonstration was not possible (due to the restrictions of lockdown) we decided to create a 1:1 scale model from foam board and wood. This was shared with the client to give them a true sense of the product, it’s scale, and provide an early opportunity for them to input. At this point decisions were made to reduce the height of the unit and modify the chassis.

1:1 scale model from foam board and wood

A Proof-of-concept chassis prototype was then fabricated in metal. This was sent to the University team to give them the framework to insert and mount their internal components. Any modifications to the chassis would be implemented into a revised design.

This project was all about creating an aspiration and vision for Respiratone as a medical device. It’s moved forward quite considerably, from an academic theme to being both clinically and commercailly focused. It has given the Durham University team first-hand experience of the product design process, and the importance and value it brings. And being involved from the start has ensured their insights were captured, and amendments implemented. We look forward to evolving it further.

““Pd-m understands research and understands how academics come up with good ideas. They can then take those ideas and show that there is a pathway to commercialisation. It is great to be guided along that path by professionals that know what they are talking about. And the fact that they can make something look really attractive must mean that they are good designers first and foremost.””