It’s not often you receive a phone call that makes everything else pale into insignificance. But when a long-standing client of ours, a surgeon who works at Leeds Teaching Hospitals Trust, recounted the chilling PPE situation he and his colleagues found themselves in at the outbreak of Covid-19, we knew we needed to act.

© Guardian News and Media Limited.

© 2020 MGN Limited

A quick look at the market showed it was being inundated with lots of 3D printed face shields made by well-intentioned individuals from local schools and businesses. All with a desire to help, but without the experience of designing medical products, or the necessary knowledge of medical standards, restrictions or processes. This make shift approach was slow and environmentally wasteful, some products even posing a risk to NHS staff.

We undertook an initial design sprint to explore numerous ideas, considering the limited availability of clinical grade materials, and the manufacturing restrictions of a country in lockdown. It soon became clear that the ideal solution needed to be both re-usable and rapidly scalable - quick and inexpensive to manufacture at high volume. But most importantly safe and easy to use.

We developed card models in our workshop, reviewing progress with our surgeon before advancing into CAD and a phase of iterative prototyping - then enlisted the help of a local laser cutting manufacturer to create market ready samples for evaluation.

Moving through this feedback loop between manufacturer and surgeon a number of times, we developed and refined the prototype until it met the needs of a clinical environment. Soon achieving a high-quality, medical grade solution.

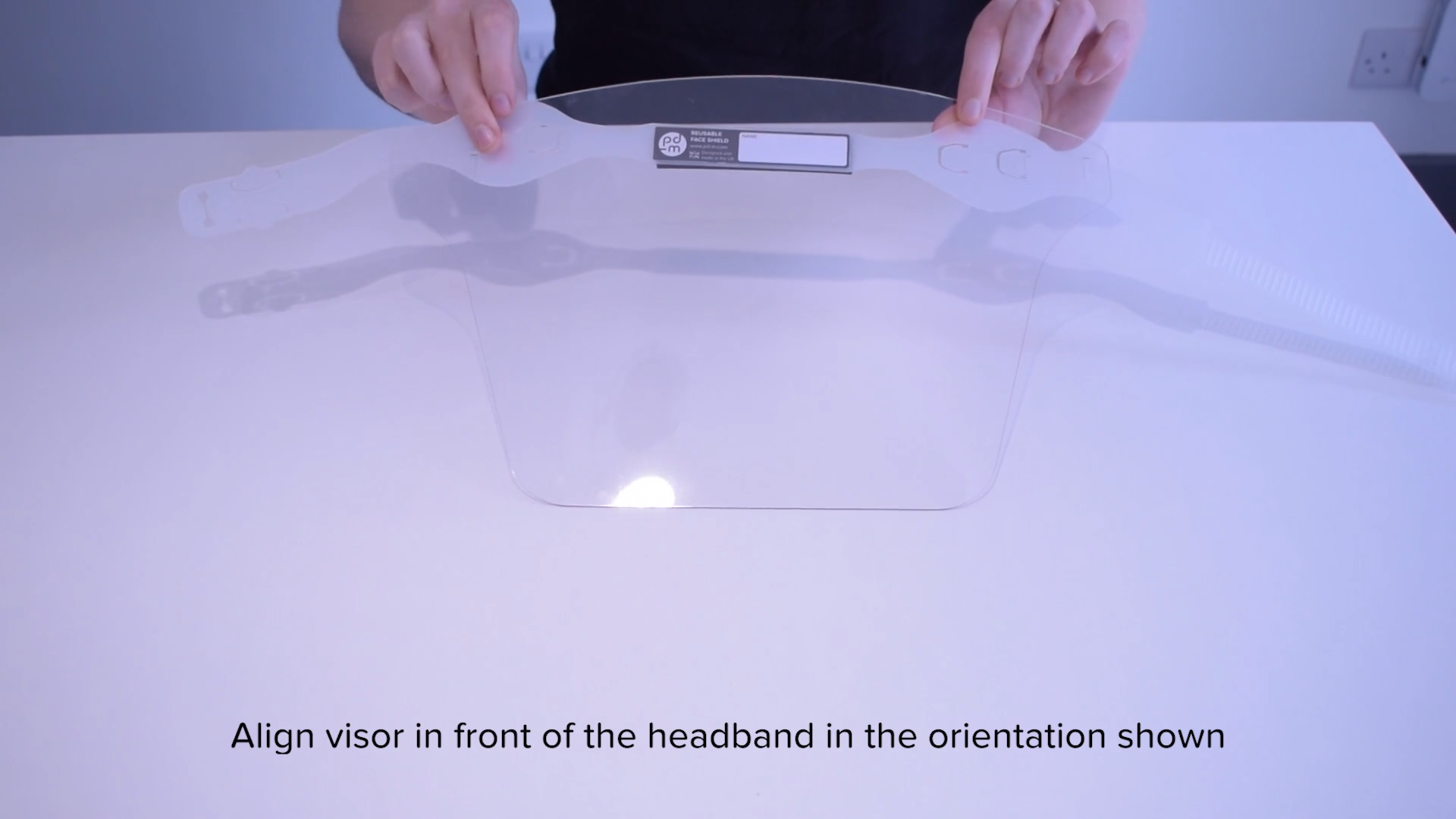

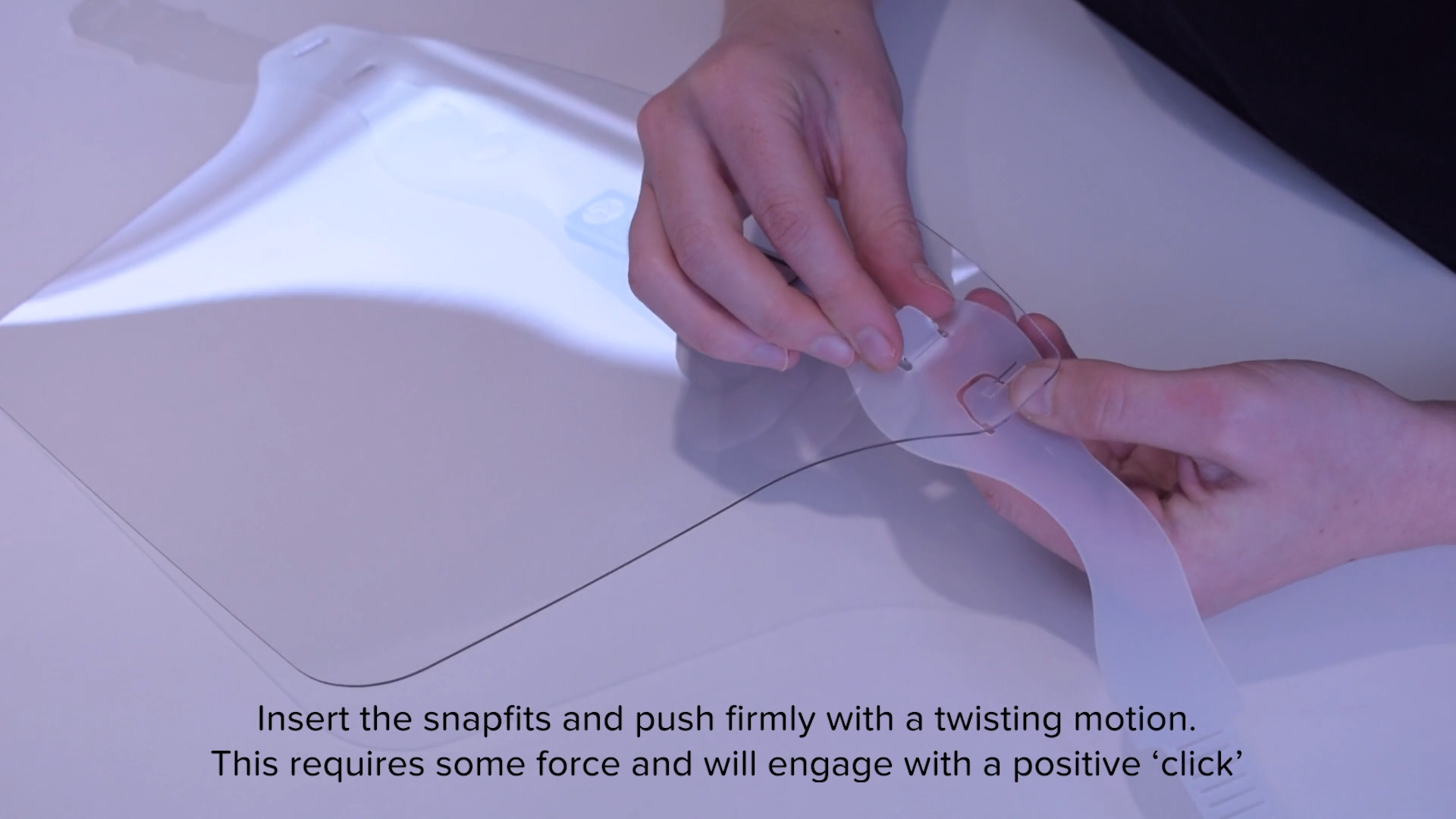

The re-usable face shield is lightweight, comfortable and easy to clean. The clever yet simple design makes it incredibly cost-effective to both produce and distribute. And consisting of just two elements, it’s easy to assemble and adjusts to fit any head shape perfectly.

We funded the production of an initial 1,500 face shields, many of which were donated to Harrogate Hospital and also St George’s Hospital in London. We obtained feedback from the clinicians in terms of the efficacy of the product and went on to successfully gain a CE mark for the PPE.

As we return to our new normal and more people start returning to work, we’re finding these face shields can also be used effectively for many different purposes; essential facilities management engineers, community workers, GP surgeries, shops, car showrooms, nurseries and schools. The list goes on!

““Sadly Covid-19 has affected people from all walks of life. When it unravelled, as a team we felt pretty helpless, especially when we knew that people close to the business were on the front line. I think this project shows the Pd-m team at their best; being agile, focused and delivering world-class innovation. As the business leader I have been humbled by the dedication of my team working together through difficult circumstances. We’re happy that we’ve done our bit”.”