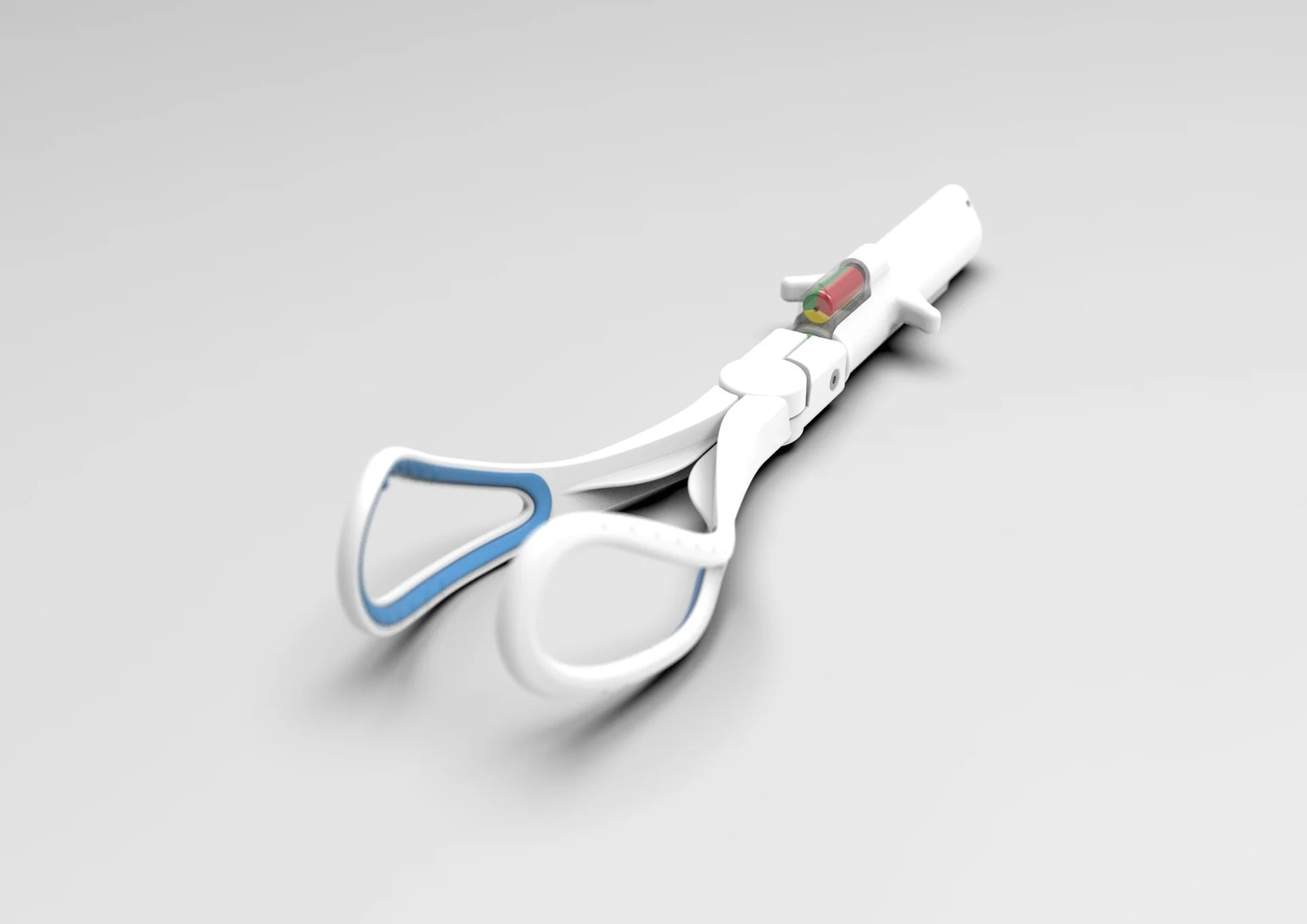

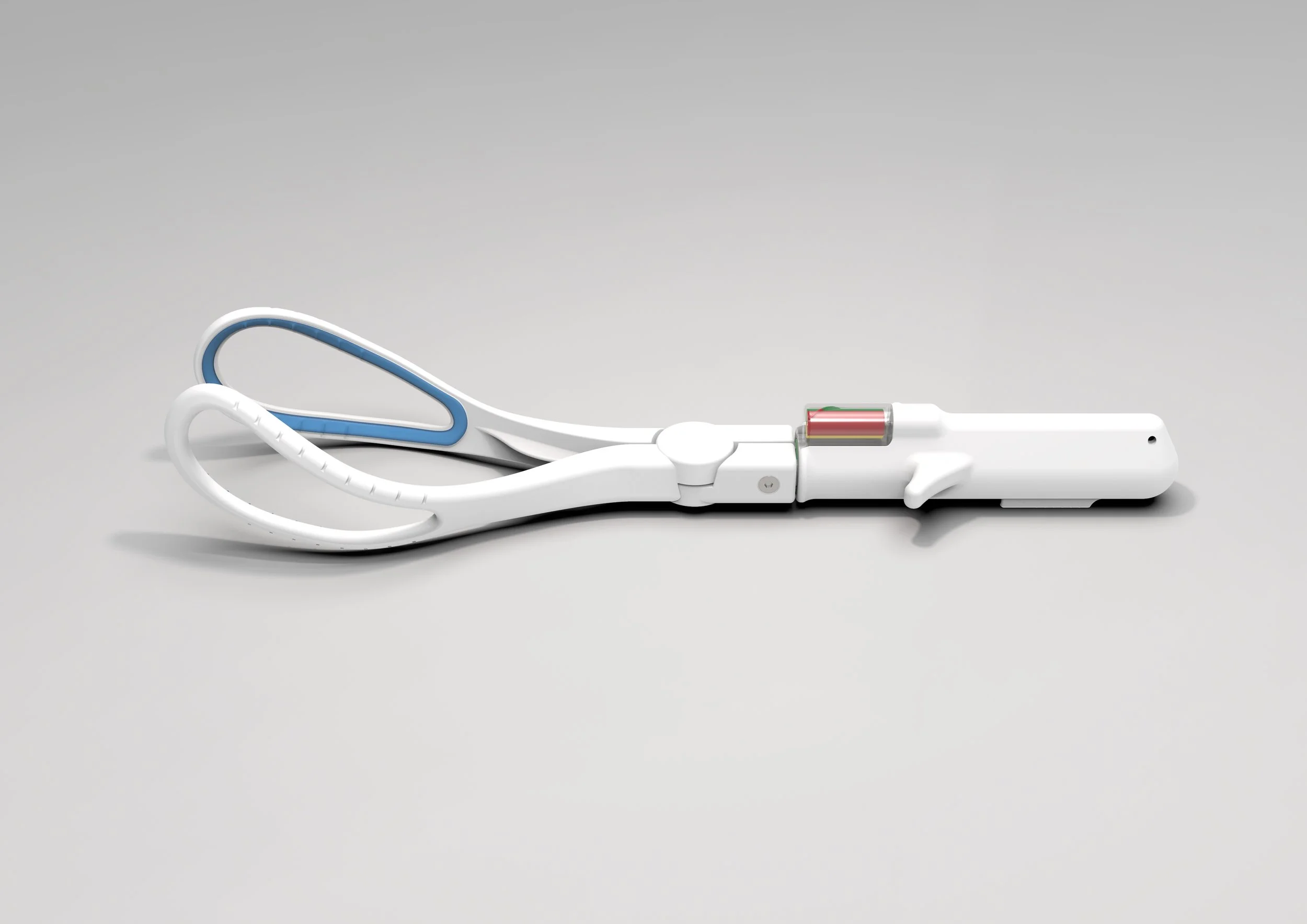

Obstetric Forceps

Designing Safer, Measurable Traction for Obstetric Forceps

Impact: xxxxx

Brief

To help obstetrician Alex Oboh solve a critical safety gap in forceps-assisted delivery: there was no way to measure traction (pull) force in real time, and no data-backed guidance on what “safe” looks like during a high-pressure birth.

Services

Clinical & user research, Concept Development, Prototyping, Engineering, CAD, Design for Manufacture (DFM), IP support.

Deliverables

Clinical & user research, Concept Development, Prototyping, Engineering, CAD, Design for Manufacture (DFM), IP support.

“The Pd-m team worked really closely with us and were an integral part of the project team. They really understood the brief and what the product needed to do, producing a design that allowed us to file both design right and patent applications. We have subsequently licensed the IP to a medical device company for manufacture and the work that Pd-m did has certainly shortened their development timescales.”

Case Study

From the start, this was a project where safety came first. Obstetric forceps have barely changed since 1752, and in the delivery room there’s still no way to know exactly when to stop pulling.

Working with Medipex, Hull and East Yorkshire NHS Trust, and obstetrician Alex Oboh, we set out to do two things: gather the evidence on safe traction, and turn that knowledge into a product that could help clinicians apply it in real time.

Finding the Safe Limits

The challenge was that there is no agreed data on “how much force is enough.” So we started with hands-on anatomical studies using mannequins, measuring and analysing the pull needed in different scenarios. This gave us clear force ranges, the level of accuracy required, and what kind of signals clinicians would need to see or feel in the moment.

Prototyping and Refining

With those numbers in place, we began building and testing prototypes. We explored:

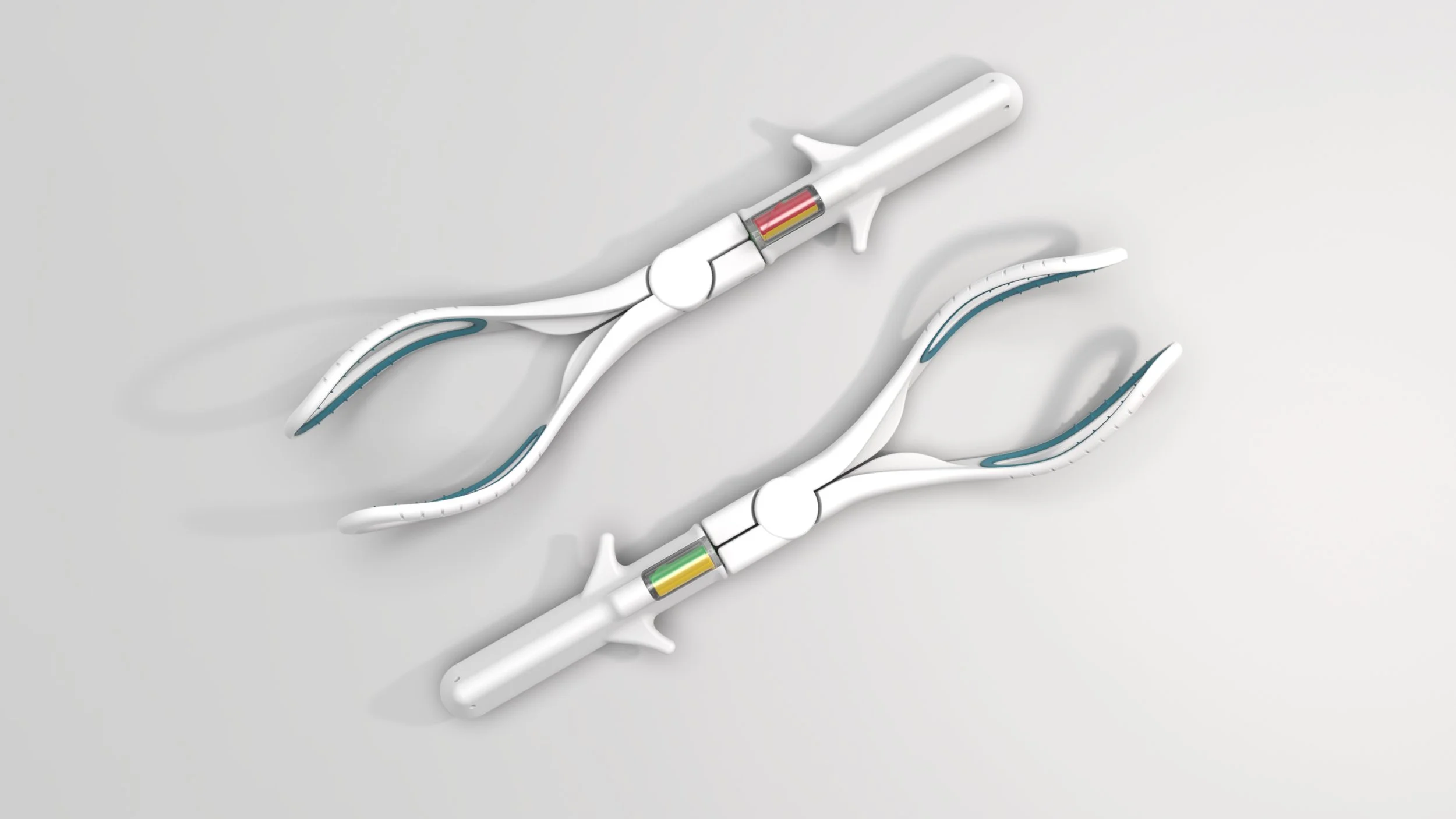

Different ways to measure force, from mechanical gauges to built-in sensors.

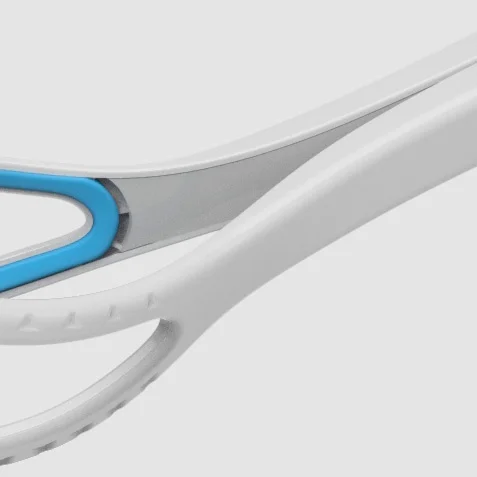

Materials that were strong, easy to clean, and comfortable to grip with gloves.

Simple, clear feedback that wouldn’t distract or overload the user.

Designs that would fit smoothly into existing workflows without slowing anyone down.

Every round of testing made the design more accurate, easier to use, and simpler to manufacture.

Ready for Manufacture

We designed the final product to be dependable, consistent, and straightforward to assemble. By involving suppliers early, we could choose the right materials and tolerances to keep costs down while keeping performance high.

The Result

The final design gives obstetricians a practical, theatre-ready tool that measures traction accurately — backed by real data and engineered to last. The work led to multiple medical device awards, a design right and patent application, and the product has since been licensed to a specialist manufacturer to bring it to market.